Yuugou

Created by: greensabbath

Worklog link

Nick Falzone is no stranger to the pages of

bit-tech, and readers will surely remember his awesome

Sangaku case. Well, it's time for something new from the master woodworker.

"After many months of planning and a little bit of actual work, my second custom case is ready to begin.

The case is based on a few of my past furniture projects along with what i learned from Sangaku. This time it will be watercooled and the components will be fully stealthed and sound deadened for something that should be amazingly quiet.

The main material for the interior frame will be aluminum which I will anodize type II black (I think). and the outer frame material will be cherry and sitka spruce with real rice paper this time and improved lighting."

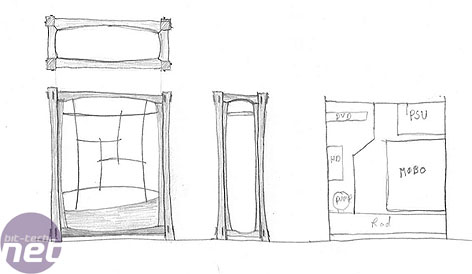

Thankfully, Nick's CAD skills and wood working skills are a little better than his pencils!

Making the frame of the case relies on some pretty nifty joints. According to Nick, the joint "Requires no glue, is solid as a rock, and can be taken apart easily." Sounds like a good start.

"I also hope to not use any glue/nails/screws for any of the wood parts of this case since the joinery will be enough to hold it. The outer case will slide over the inner frame this time. The inner case actually functions as an almost complete computer case on its own but the outer frame should give it a look similar to Sangaku but more modern looking."

You can see how this now starts to come together. The case is very, very big - check out the CD drive for comparison.

The components themselves will be mounted within an inner aluminium chassis. To this end, Nick cut some grooves in the wood to accept the metal sheeting. There are also grooves that need to be put in to accept some of the wood detailing, including some docorative koa wood. "This wood is amazingly beautiful in person with a tremendous amount of curl on the koa. The maple also has a bit of figure to it."

To get the curve of the wood, it was soaked in water and then put in the microwave. This gives the wood some more bend. After some time in a bending brace, this is the kind of result you can end up with.

The

log is chock full of fantastic details shots of the wood working process. If you've ever been even remotely curious about the tools and the processes required to do a professional job of wood manipulation, it's a fascinating read.

Want to comment? Please log in.